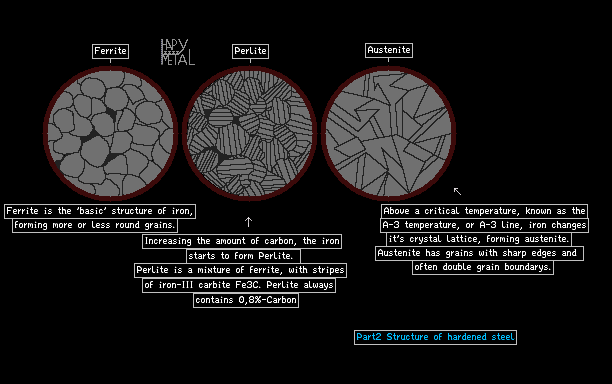

Microstructure of Iron-alloys part-1 by HapyMetal

Iron, especialy steel is a very fascinating material. With this series i want to show you the microstructure of Iron alloys. In this 1st part, i displayed the three 'basic' structures.

iron

microstructure

metal

irony

ohtheirony

science

Comments

-

godhydra 29th Jun 2016

Compared to some people on here... You Guys = Einstein - Me = A blobfish. (Nice save, though. xD)

Compared to some people on here... You Guys = Einstein - Me = A blobfish. (Nice save, though. xD) -

explorer 29th Jun 2016

Its my hdd plate

Its my hdd plate -

HapyMetal 29th Jun 2016

Mainly durasteel has a lucasetic microstructure, but it's difficult so see because it's almost impossible to etch the surface. ;-)But seriously, there was really a patent in the late 70s named 'plasteel'. It was a compound of fiberglass and steel-wool, but it never worked really well, so it's almost forgotten today.

Mainly durasteel has a lucasetic microstructure, but it's difficult so see because it's almost impossible to etch the surface. ;-)But seriously, there was really a patent in the late 70s named 'plasteel'. It was a compound of fiberglass and steel-wool, but it never worked really well, so it's almost forgotten today. -

Dorito_tRF 29th Jun 2016

in one of the saves you you should do one on durasteel and plasteel they are real things

in one of the saves you you should do one on durasteel and plasteel they are real things -

Sandwichlizard 27th Jun 2016

nice SET of saves. educational. very cool.

nice SET of saves. educational. very cool. -

MEANY 27th Jun 2016

Another amazing save from you. Well done.

Another amazing save from you. Well done. -

HapyMetal 27th Jun 2016

correction: "...there are many different alloys..." what i mean was "there are many different IRON-BASED alloys..." sorry for that.

correction: "...there are many different alloys..." what i mean was "there are many different IRON-BASED alloys..." sorry for that. -

HapyMetal 27th Jun 2016

@lare290: Basically yes, but it's possible to stabelize Austenite at room-temperature and below by adding, for example, Ni to the alloy, but you have to go over A3 one time. Austenetic steel has a lower conductivity and is less sensitive to corrosion. This is known as 'stainless steel'. The first basic alloy itshelf is known as 16-10-V2a, but there are many different alloys that have an austenetic structure at RT.

@lare290: Basically yes, but it's possible to stabelize Austenite at room-temperature and below by adding, for example, Ni to the alloy, but you have to go over A3 one time. Austenetic steel has a lower conductivity and is less sensitive to corrosion. This is known as 'stainless steel'. The first basic alloy itshelf is known as 16-10-V2a, but there are many different alloys that have an austenetic structure at RT. -

lare290 27th Jun 2016

So.. austenite is basically heat-treated iron?

So.. austenite is basically heat-treated iron? -

Matera_the_Mad 26th Jun 2016

-1 for apostrophe misuse (JUST KIDDING)

-1 for apostrophe misuse (JUST KIDDING)